The aim of this project is to carry out basic academic research to develop next-generation greenhouse gas substance conversion technologies and applied research for their societal implementation, with the aim of achieving a sustainable society and providing solutions to pressing international and domestic regional issues.

Examples: carbon dioxide conversion, biomass utilisation, shale gas revolution, plastic waste management, 3D printing, smart materials, etc.

To be jointly undertaken by Nippon Steel Corporation, Chiyoda Corporation, Nittetsu Engineering Corporation, Hichem Corporation, Mitsubishi Corporation, ENEOS Corporation.

What is PX (paraxylene)? Paraxylene is a chemical necessary for the production of polyester fiber and PET bottles.

Chiyoda Corporation has built and commissioned a pilot plant(upper left) that has successfully isolated paraxylene from CO2(upper right).

The next generation of new catalysts is also being prepared. (Nature Comm, 2024 Sept)

Polyester fiber made from part of the CO2-derived PX produced at the pilot plant has been adopted by THE NORTH FACE (Goldwyn Co., Ltd., Headquarters Toyama Prefecture) as the uniform for the sports climbing team at the Paris Olympics (Japan, USA, Korea, Austria, etc.)!

★It is also sold in stores as T-shirts.

Jointly undertaken by ENEOS GLOBE Corporation, Nippon Steel Corp.

The targets have been achieved after several on-site operations using CO2 emitted from the IGCC thermal power plants of Chugoku Electric Power Co. and Power Development Co. in the Seto Inland Sea.

The next generation of new catalysts has also been prepared. (Nature Comm, Jan 2024)

IGCC stands for Integrated Coal Gasification Combined Cycle.

It is a power generation system that gasifies coal and combines two forms of power generation – gas turbines and steam turbines – to produce combined cycle electricity.

Other…

Joint research with Honda (low carbon fuels) is ongoing.

A paper on the synthesis of low-carbon petrol from CO2 has been published in the top journal Angew Chem (Aug 2024).

Jointly undertaken by Co-funded by JAPAN COAL FRONTIER ORGANIZATION (JCOAL), ENEOS Corporation, Tomoe Shokai Co.

Thailand: Chulalongkorn University, Northern Renewable Energy Co., Ltd, PTT

SATREPS is a programme to promote international collaborative research between Japan and developing countries to solve global problems.

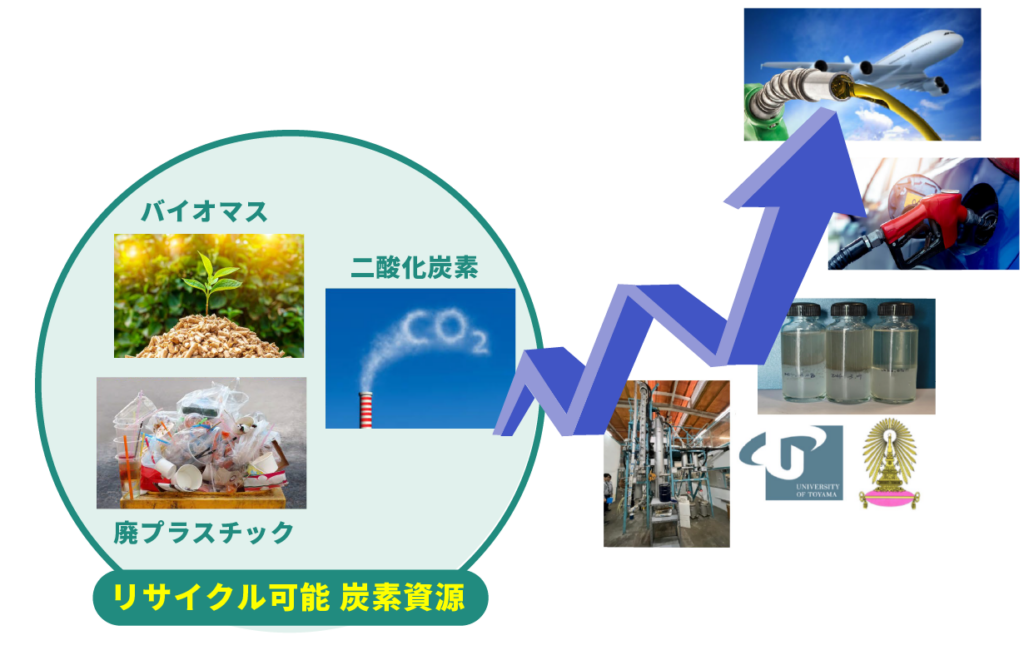

It develops direct synthesis methods and new catalysts for low-carbon fuels.

(In-Text Citation: Tsubaki Lab 2018 Nature Catalysis journal article, 2018 Nature journal editorial)

We develop technologies to convert biomass resources into liquid fuels.

We develop technologies to produce alternatives to fossil fuels from renewable resources, contributing to resource and environmental issues.

Research and development continues after the project is completed.

Our project accepts exchange students from Thailand, China, Korea, and other countries.

We are working to internationalize our research while developing new ideas in this diverse environment.

Thailand

・Chulalongkorn University(University Exchange Relationships)

China

・Dalian University of Technology(University Exchange Relationships)

・School of Materials Science and Engineering, central south university of forestry and technolory(Faculty Exchange Relationships)

Korea

・Sungkyunkwan University

Taiwan

・ITRI:Industrial Technology Research Institute

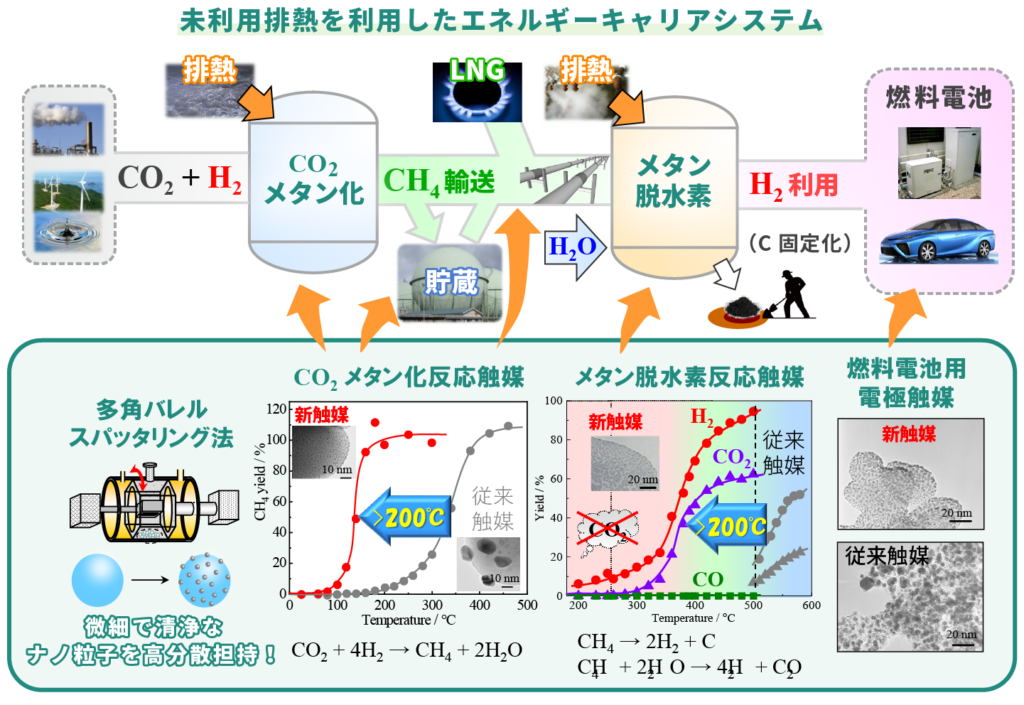

To reduce CO2 emissions, which are considered the main cause of global warming, our research aims to construct an energy carrier system using unused waste heat that will contribute to the realization of a carbon-neutral society. We have created active nanocatalysts using our proprietary “polygonal barrel sputtering method” and are also investigating the following;

・CO2 methanation reaction to produce natural gas (methane) from exhaust gas

・Methane dehydrogenation reaction to produce hydrogen from methane at low temperatures

・Improvement of performance and cost reduction of electrocatalysts for fuel cells used in ENE-FARM and automobiles.

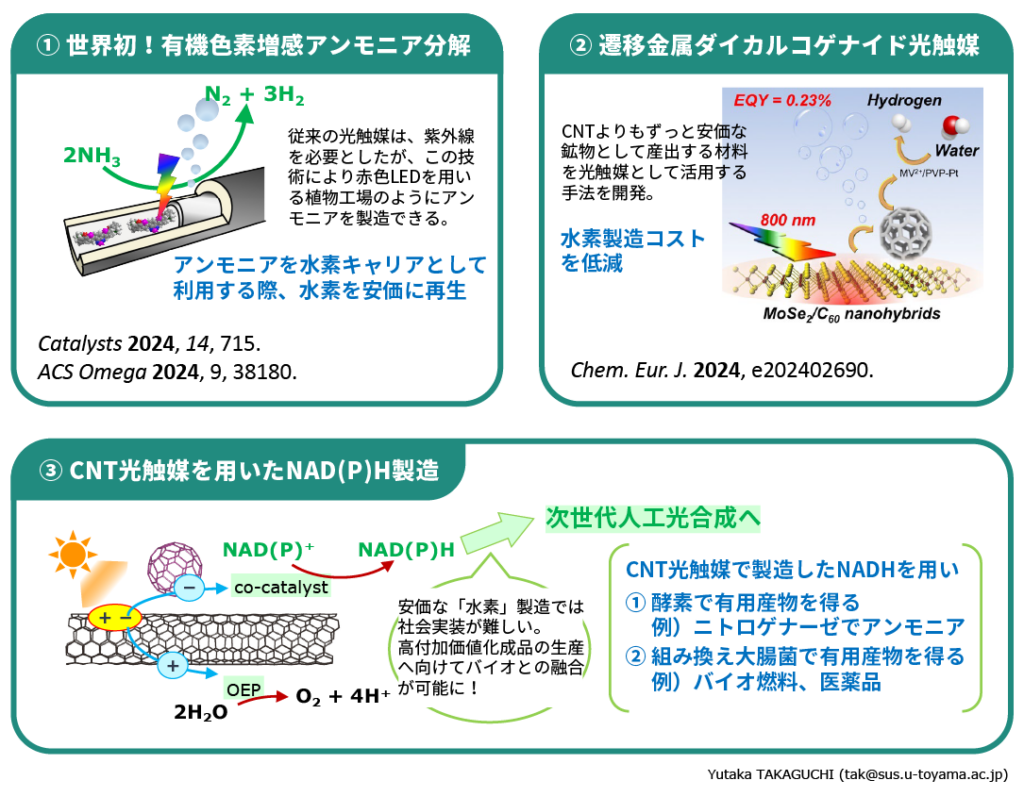

We are developing energy carrier and useful material production (artificial photosynthesis) technologies that use sunlight as an energy source. The aim is to contribute to carbon neutrality by producing substances from CO2. Nanomaterials are characterized by high functionality and high activity through surface modification and can be applied to environmental purification and sensors. The use of nanomaterials allows much better control of active wavelengths and reaction selectivity.

The project contributes to the development of various projects by utilising Toyama Prefecture’s unique natural environment (one of the best geothermal potentials in Japan, abundant forest and water resources), and by assessing and analysing the environmental impact of natural (geothermal and forest) development to create a customised, localised, carbon-neutral society.

In close collaboration with the Research and Development Division, this project aims to contribute to the development of a sustainable energy society by deepening international technical exchanges to develop next-generation biofuel technologies and realise a low-carbon society.

Specifically, bench-scale testing of jet fuel synthesis technology using gases derived from CO₂, biomass and plastic waste has been carried out in Thailand, and fuel synthesis with high selectivity has been successfully achieved; collaboration with Airbus, Honda Motor Co.,Ltd.,JFE Holdings.Inc.,ITRI

In Aluminum Research Center (ARC), the aluminum recycling process is researched and developed using equipments designed for the R&D on recycling technologies, with the aim of carbon neutrality in the future.

A research group in ARC’s refining field is developing an upgrad recycling technology for aluminum.

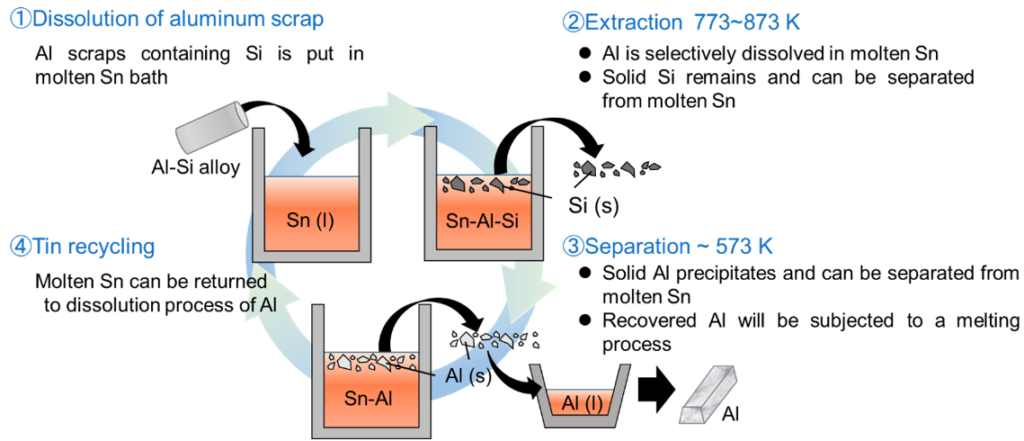

Development of upgrade recycling technology of aluminum through extraction and phase separation

Department of Materials Design and Engineering, School of Sustainable Design, University of Toyama Prof. Hideki Ono

YKK AP Inc., Sankyo Tateyama, Inc., Aisin Keikinzoku Co., Ltd., HARITA Co.,Ltd., AISIN CORPORATION, NEC Corporation

Compared to other common metals, large amounts of energy are required to produce aluminum from natural ore. On the one hand, aluminum recycling requires 97% less energy than primary production. Accordingly, if aluminum scrap is recycled and utilized, aluminum products can be produced with less environmental impact.

Currently, cast aluminum alloys (e.g. engines of automobiles) are produced using 100% recycled aluminum. However, the used amount of recycled aluminum for wrought aluminum alloys (e.g. sash and body of automobiles.) remains at 10 %. Accordingly, it is necessary to develop upgrade recycling technology for aluminum scrap, and silicon removal technology is particularly important for recycling cast aluminum alloys into wrought alloys.

aluminum and implementation in the society

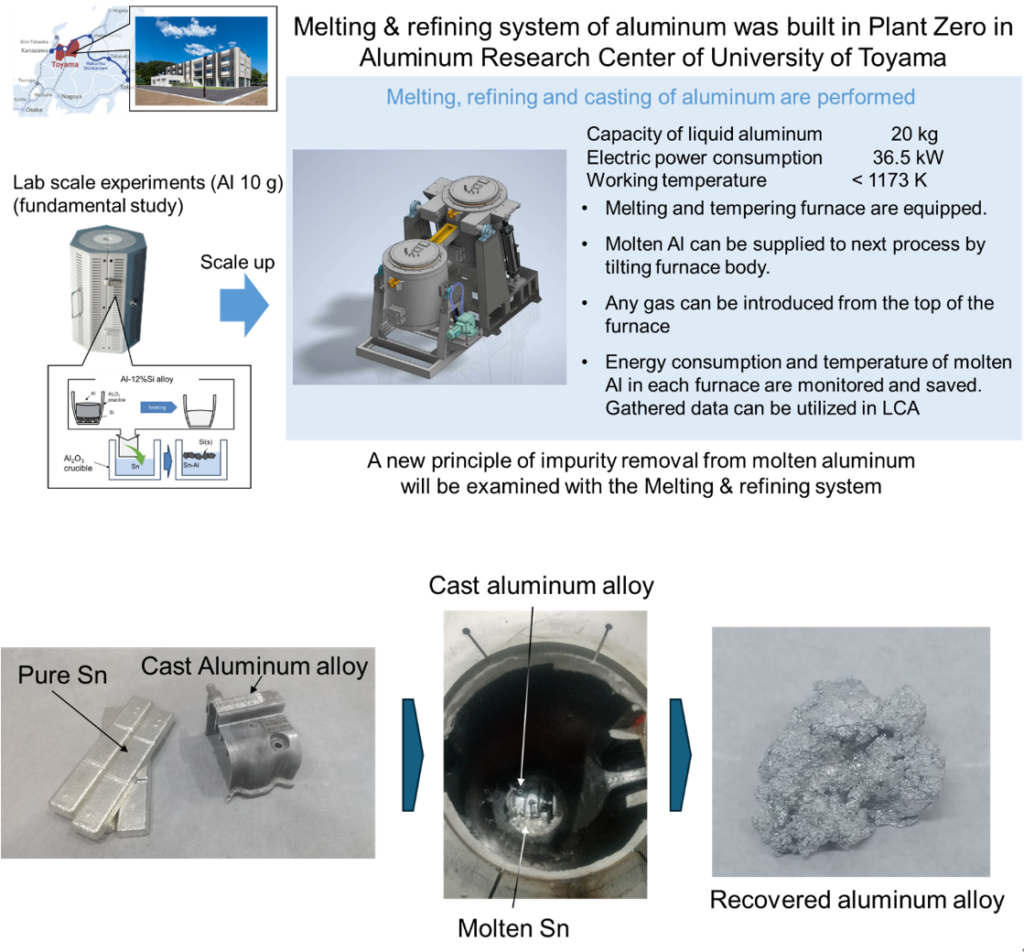

The research on the new principle of silicon removal from aluminum was started in the lab-scale experiment(10g). Currently, a bench-scale experiment (~ 10 kg) is underway for the implementation of the recycling technology in society using the melting & refining System of sluminum.

Aluminum alloy with less silicon content was recovered from cast aluminum alloy through the bench-scale experiment.

Removal of impurities has been an issue for recycling aluminum. The recycling technology for aluminum scraps developed in ARC will enhance the utilization of resources contributing to the sustainable development of society.

We are planning to offer a lecture titled ‘Introduction to Carbon Neutrality’ (tentative name) as a common postgraduate subject from FY2026.